Circulation Heaters In-Line Heaters Guide:

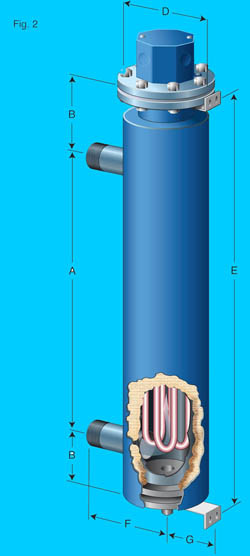

Circulation/Inline Heaters-Components

Circulation/Inline Heaters-Components

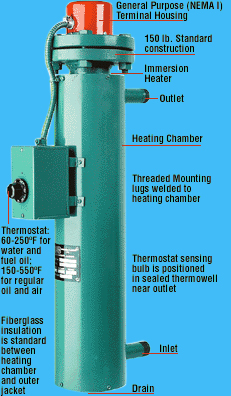

Flanged 150 lb Circulation Heater-Nema 1 Enclosure

Flanged 150 lb Circulation Heater-Nema 1 Enclosure

Circulation Heaters, Re-Circulation Heaters

Circulation Heaters, Re-Circulation Heaters

CIRCULATION HEATERS PRODUCT DESCRIPTION GUIDE:

Circulation heaters,also referred to as in-line or re-circulation heaters are used for heating flowing liquids and gases. A Non-pressurized or highly pressurized fluids can be heated very effectively using either direct or indirect circulation heating. A wide variety of standard designs and custom engineered power ratings, sizes, flow capacities and options are available to fulfill most any application needs.

NPHcirculation heatersfeature all-welded constructionof the steelshroud and flanges, hydrostatically pressure-tested ports, heavy-duty metal-sheathedheating elementsof Incoloy or steel, galvanized or carbon steel containment pipe, NEMA1 terminal housings, bulb & capillary thermostats or solid-state controls, plus up to a 150-lb. forged steelflangewith bolt construction connecting the terminal housing and containment vessel.

Circulation Heaters: Specifications, Manuals, Technical Letters & Tips:

Circulation Heaters Features:

- High efficiency heat transfer

- Pressure ratings to 600 lbs

- ANSI Standard NPT or ANSI Class 150 connections

- Heaters could be screw plug or flanged

- Circulation Heaters, Re-Circulation Heaters, Industrial Circulation Heaters Stainless steel construction with Canadian Vessel Registration

- Various housing options available NEMA 4, 4X, explosion proof

- Suitable for steam, oils, chemicals, gases, corrosive solutions

Optional Features

- Weather Proof Insulated Shroud

- All Stainless Steel Construction

- ASME Section 8 Construction on Vessel

- High Pressure Construction

- High Temperature Ceramic Fiber Insulation

- Passivation on all Wetted Surfaces

- Other Sheath Materials: Carpenter 20, Model 400, Inconel 600, Hastelloy, and Titanium

Applications Factors

Heater selection is influenced by the following parameters:

- � The Heated Medium, Viscosity, Specific Heat, Density and Corrosive Properties

- The Presence of Contaminants in the Medium

- The Corrosion Resistant Properties of the Heated Medium

- The Sheath Watt Density of the Heating Elements (the watts/in²) and the Flow Rate of the heated moedium

- The Vessel Design and Materials of Construction

- Times, Temperature, and Pressure

Pressure Vessels

- All standard pressure vessel (tank) materials are rated to 150 lb. and made from:

- Carbon Steel

- 304/316 Stainless Steel

- All catalog pressure vessels (tank) are steel unless otherwise noted.

COMMON SHEATH MATERIALS

Sheath Material | Application | Watt Density Watts/in� |

| Copper | Potable water | 40-80 |

| Steel | Fuel Oils, Hydraulic Oils | 20-25 &12-25 |

Stainless steel | De-Ionized, R-O, Process Water Mild Acids | 40-80 12-25 |

| Incoloy 800 | Water, Mild Alkaline Solutions, Air and Gases, Maximum Sheath Temperature 1400ºF | 10-125 |

| Inconel 600 | Water, Very Alkaline Solutions, High Temperature Air And Gases Maximum Sheath Temperature 1500ºF | 10-50 |

| Titanium | Sea Water, Very Alkaline Solutions, Some Acid Solutions | 10-45 |

Circulation Heaters Specifications / Design Capabilities:

Voltages. . . . . . . . . . . . . . . .120 to 600 Volts

Inlet/outlet. . . . . . . . . . . . . .N PT 1 /2" to 21 /2

Flanges 2" to 14" 16" to 24" on request

Heater. . . . . . . . . . . . . . . . .NPT or flange mount as required

Wattage's. . . . . . . . . . . . . . .Varied from 150 watts to 1 Megawatt

Sheath Materials. . . . . . . . . . Titanium, Monel, Incoloy, 316/304 Stainless,

Steel Copper, Carbon Steel

Max Temperatures. . . . . . . . . Incoloy 1600 degrees F (870 C)

304 / 316 Stainless Steel 1200 degrees F (650)

Steel 750 degrees F (400 C)Copper 350 degree F (175 C)

Pressure Rating. . . . . . . . . . . 150, 300 or 600 Ibs

Flange Materials. . . . . . . . . . .Standard Carbon Steel or 316/304 Stainless

Gaskets. . . . . . . . . . . . . . . . Rubber, Asbestos Free, or Spiral wound

Terminal Enclosures. . . . . . . . General Purpose (NEMA 1 ),

Moisture Resistant (NEMA 4), Corrosion

Resistant (NEMA 4X), Explosion Resistant (NEMA 7),

Explosion Moisture Resistant (NEMA 7/4)

Temperature control. . . . . . . .Thermocouple, RTD, or Thermostat

High Limit. . . . . . . . . . . . . . . High Limit Thermocouple, Hi Limit Tstat,

Certification. . . . . . . . . . . . . ASME, CRR, Heater & Vessel certification

We Ship Our Kapton & Process Heaters To OEM’s & Industry World Wide