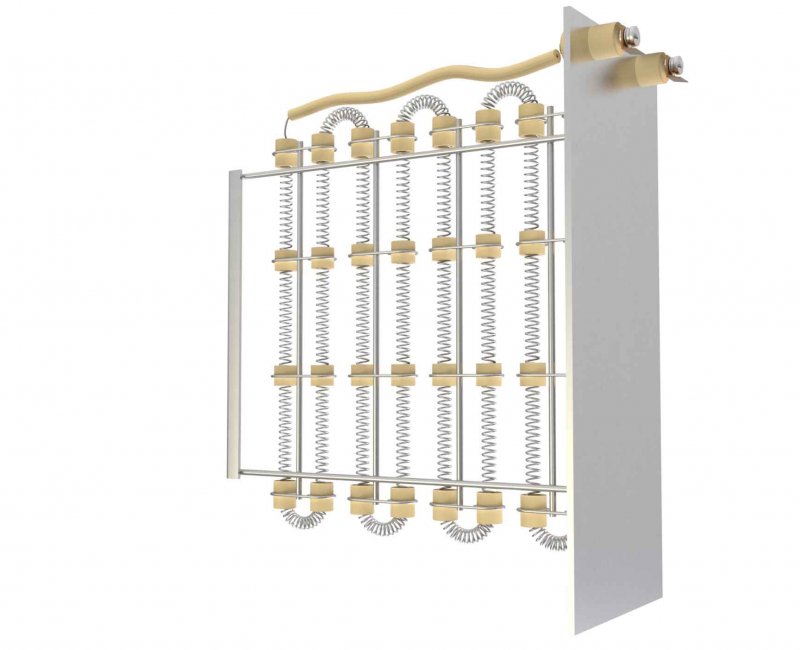

Open Coil Air Heating Elements for Convection, Duct & Oven Heating

|

|

|

Open Coil Heating Elements-Used For Duct Heaters, Ovens and Air/Convection Heating Applications

Open Coil Heating Elements-Description Guide:

Open coil heating elements are coiled resistance wire fixed onto a supporting steel or aluminum frame with

ceramic insulators. The selection of the correct wire gauge, wire type and coil diameter requires quite some

experience. There are standard elements available on the market, but quite often they need to be custom

built. Open coil air heaters work best below air velocities of 80 FPM. Higher air velocities could cause the

coils to touch each other and short out. For higher velocities, select a tubular air heater or finned tubular heaters.

ceramic insulators. The selection of the correct wire gauge, wire type and coil diameter requires quite some

experience. There are standard elements available on the market, but quite often they need to be custom

built. Open coil air heaters work best below air velocities of 80 FPM. Higher air velocities could cause the

coils to touch each other and short out. For higher velocities, select a tubular air heater or finned tubular heaters.

Review General Applications:

The big advantage of open coil heating elements is the very quick response time. Most of these elements

need a constant airflow over the resistance wire, but if the watt densities are low enough they may not

burn out in still air.

Nichrome resistance wire open coil elements are used extensively in convection heating applications,

R&D and as replacement coils in duct heaters, portable heaters and air process heaters, as well as in

some infrared applications such as vacuum forming /thermoforming.

Before we can build a heater, we need to know at least the airflow (CFM), Delta T ( i.e. change in temperature),

volts and watts.

need a constant airflow over the resistance wire, but if the watt densities are low enough they may not

burn out in still air.

Nichrome resistance wire open coil elements are used extensively in convection heating applications,

R&D and as replacement coils in duct heaters, portable heaters and air process heaters, as well as in

some infrared applications such as vacuum forming /thermoforming.

Before we can build a heater, we need to know at least the airflow (CFM), Delta T ( i.e. change in temperature),

volts and watts.

Specifications:

- High Quality grades of NiCr resistance wire (80-20) & (65-35)

- Resistive wire gauges from 6 Gauge wire up to 38 Gauge available

- Coil diameters from .250 inch dia up to 0.875 inch dia

- Arrow Ceramic/steatite clips (insulators) or rounded ceramic clips available

- Termination options include screw type or other alternatives

- Custom stretch ratios available

Features & Benefits:

Quick heat up time & easily replaceable

Outside diameters: 1 7/8'' and 2 ¾''

Lengths: 60-320'' (5-26 ft)

Single element ratings: 4-20 kW

Pipe Surface: 3-12 W/In2

Voltages: 240, 480 and 600V, 3 PHASE

Used in horizontal 2'' or 3'' schedule 40 NPS pipe

Equipped with high density electrical ceramic insulating supports

Can be bent in a vertical plane on at least 12'' radius

Heavy gauge bus bars

Heavy gauge resistance wire

Special ratings and lengths available upon request

Outside diameters: 1 7/8'' and 2 ¾''

Lengths: 60-320'' (5-26 ft)

Single element ratings: 4-20 kW

Pipe Surface: 3-12 W/In2

Voltages: 240, 480 and 600V, 3 PHASE

Used in horizontal 2'' or 3'' schedule 40 NPS pipe

Equipped with high density electrical ceramic insulating supports

Can be bent in a vertical plane on at least 12'' radius

Heavy gauge bus bars

Heavy gauge resistance wire

Special ratings and lengths available upon request

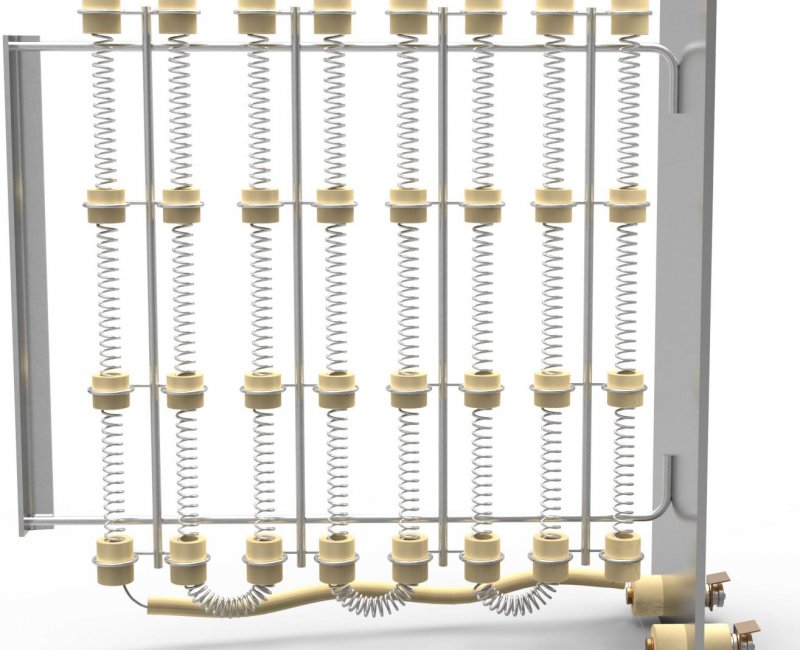

Open Coil Housing Heating Rack

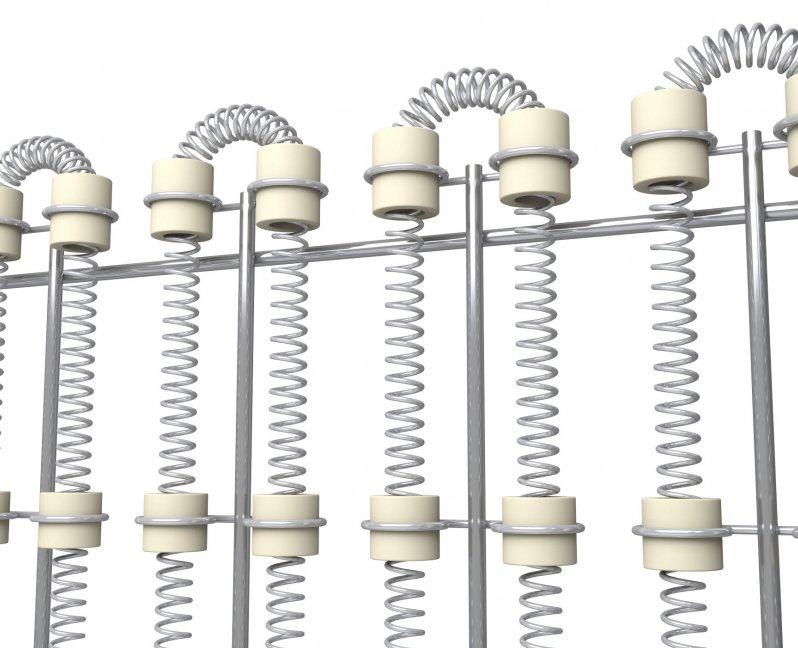

Open Coil Heating Element Close Up

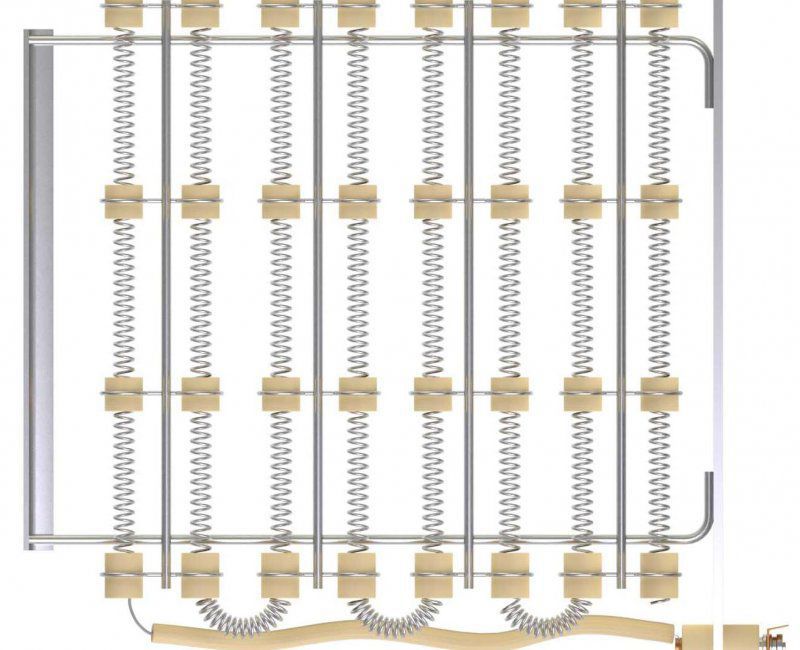

Open Coil Element Housing Style 2

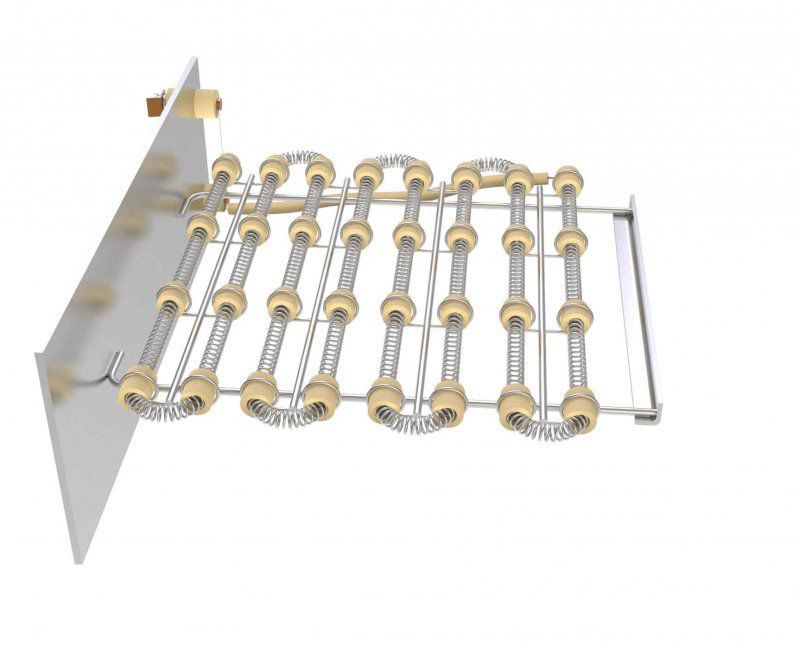

Open Coil Element Housing Angle 2

Open Coil Element Housing Angle 3

Open Coil Element Housing Angle 1

Open Coil Housing Angle 4

We Ship Our Kapton & Process Heaters To OEM’s & Industry World Wide